This project aims at reducing PET consumption in bottle production, simultaneously allowing for developing the technology for incorporating rPET (recycled PET) in an optimal and sustainable way, and also contributing for increasing the performance of its productive process.

Project profile

Project name: HEATPET: Production of bottles with a higher sustainable profile: master temperature effects on a preform for PET bottle production

Project Code: LISBOA-01-0247-FEDER-045336

Main Goal: Reinforce research, technological development and innovation

Region: Lisbon

Beneficiary: Logoplaste Innovation Lab, Lda.

Approval Date: 19-12-2019

Start Date: 01.09.2019 End Date: 31.08.2022

Total eligible cost: 562.968,36 EUR

European Union financial support: FEDER – 189.014,66 EUR

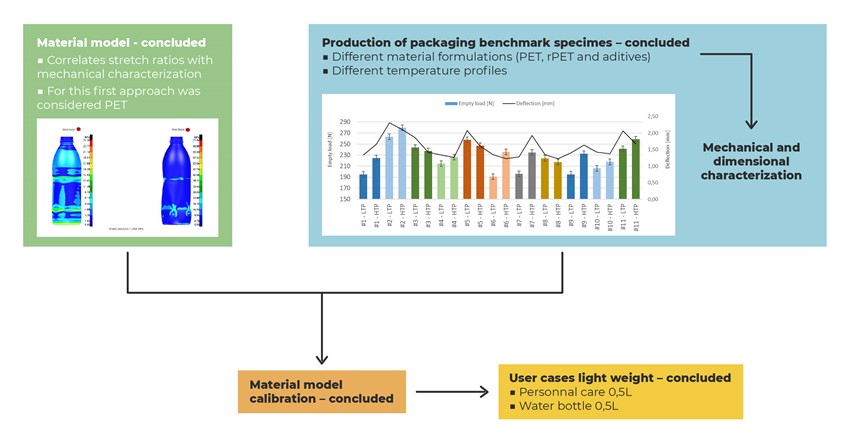

This study will start with science of materials, about PET and rPET properties, and the way they are affected by the stretch-blow process. This project will study the impact of the temperature and process characteristic in the crystalline arrangement of polymers, and its impact on bottle resistance to top load. This will allow for greater reduction in specific PET consumption for each bottle.

This project is mostly dependent of the impact of the temperature profile of the behaviour of the material, which brings out the long term identified need for greater control on the temperature profile of the preform.

Today the stretch-blow process has a serious handicap on controlling the temperature of the external profile, and there is not a technical solution for controlling the inside temperature profile when entering the mold. This bring us to the second objective of the project, which is to develop a system for measuring the external and internal temperature profile on the preform, and to control the oven in order to achieve the correct temperature profile (which is not necessarily constant along the preform).

The combination of the scientific and technological achievements will allow for greater control on the process, greater performance, better replication between machines and factories, reduction of setup time, and also allow for greater addition of rPET with optimized material control.

SCIENTIC DEVELOPMENT

Temperature /process impact into the packaging preformace

Scientific objectives focused on the characterization of temperature and production process characteristic impact on the crystalline arrangement of polymers. Studying possible correlations with bottle top load performance, and setting a path to reduce PET consumption in bottle production for the plastic packaging industry.

TECHNOLOGICAL DEVELOPMENT

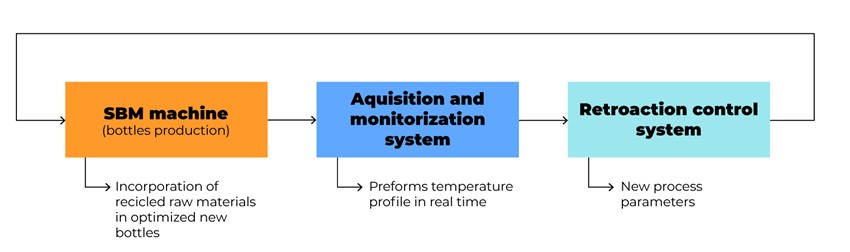

Monitorization and control system

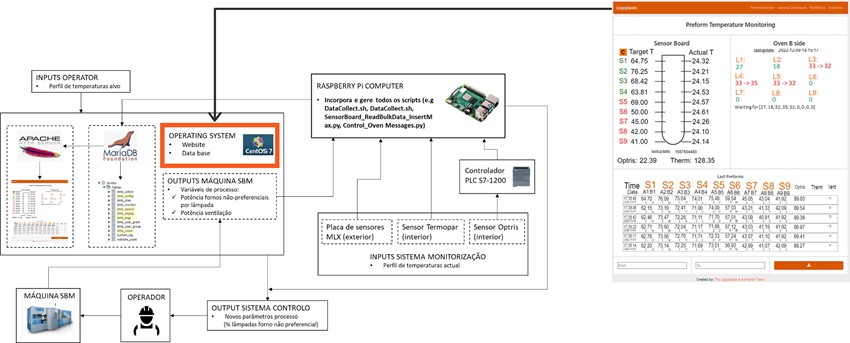

(i) Monitorization and acquisition system – we developed a system capable of monitor and acquire the temperature profile of the preforms after the non-prerational oven.

External temperature profile

Internal temperature profile

Thermal infrared camera

- Spot finder Optris Xi-400

- Used as reference and control in the tests and system validation of the infrared sensors

- Fully implemented in monitorization and acquisition system

Infrared sensor

- Optris D27CT-LT25FCB8

- Fully implemented in monitorization and acquisition system

Infrared sensors (9x) board

- Melexis MLX90632

- Plate fully developed and implemented in the monitorization and acquisition system

Thermocouple sensor

- Fully implemented in monitorization and acquisition system

(ii) Control system – We also developed a control system that, integrating the acquisition and monitoring system, is able to calculate new process parameters so that the real temperature profile converges to the target profile. New parameters are communicated to the operator through messages in a control interface.

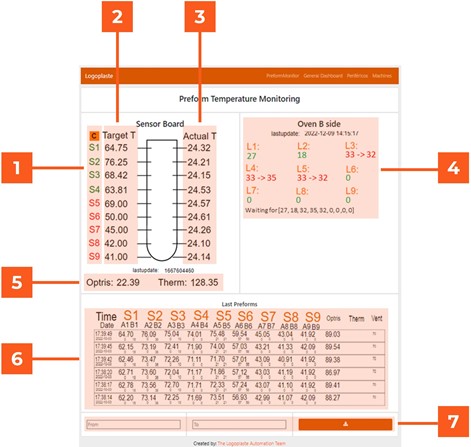

- list of active (green) and inactive (red) sensors

- target exterior temperature profile visualization

- realtime exterior temperature profile visualization

- actual lamps parameters (green) and order to operator (red)

- actual internal temperatures

- data log of previous external temperature profiles aquisitions

- raw data download >